Shipbuilding

Description of work:

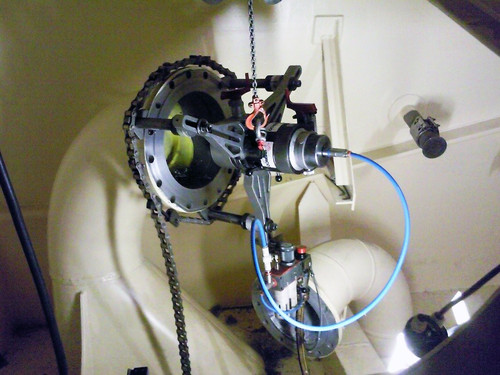

Repair of seal surfaces and grooves on two DN250 flanges and three DN 350 flanges with a machining unit SERCO TU 600 and a chain clamping system SERCO FC 745

Tolerances flatness defect : 0.1 mm/m maximum

Roughness tolerances : Ra between 6.3 and 12.5

Result : Machining respecting the requested dimensions tolerances and the roughness (Ra between 10.13 μm and 12.17 μm)