0 mm (0.00") ID

800 mm (31.50") OD

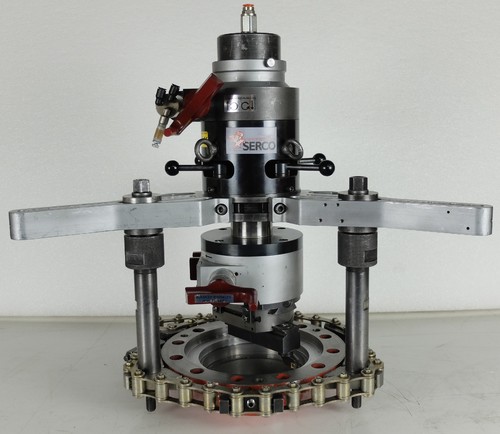

The SERCO TU machining units are designed for the repair and maintenance of virtually any component: Flanges, Grooves, Safety valves, Sealing surfaces, Hole surfaces, High pressure valves, Bolt extraction, Flat seats, Conical seats, Manholes, Diesel engine repairs, RTJ Grooves etc.The SERCO TU 800 is designed for machining surfaces. Specially designed support arms increase its capacity. The rigidity of its design also enables it to machine valve seats down to depths of 500 mm (19.7”). Like the TU400 and600, it is equipped with automatic feed systems and can be fitted with an RTJ system. The FC 1150 option, a chain clamping system specially designed for these machines, is also available.