300 mm (11.81") ID

1800 mm (70.87") OD

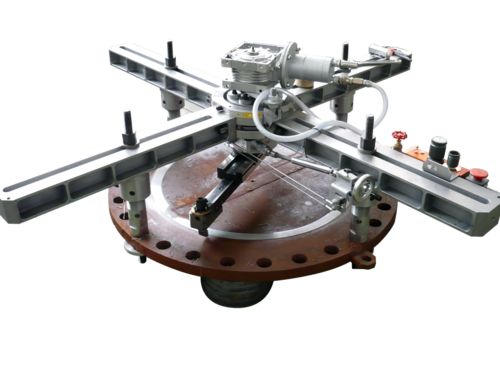

Surfacing of all types of flanges: 20 to 1800 mm (0.79” to 70.9”).The SERCO XP 1800 machine is designed on the same principles as the XP1200, with a radial movement machining head. The four mobile clamping arms have been reinforced to maintain the rigidity of the unit when machining Ø up to 1,800 mm (70.9”). This equipment is perfectly suited for flat faces, raised faces, RTJ, tongues and grooves, lens rings, Grayloc®, and compact flanges.