1000 mm (39.37") ID

2300 mm (90.55") OD

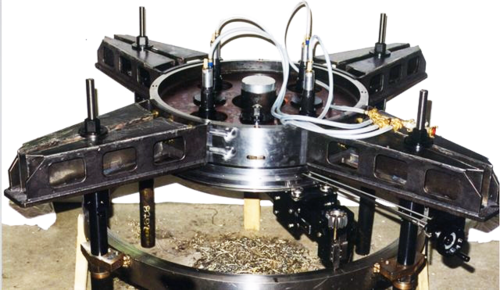

The drive system on the MS machines is more powerful than on the XP machines, which enables them to carry out core-drilling operations. The high torque of the motor is adapted to machining seriously damaged surfaces or where deeper passes are required. Among other things, the MS 600machine is equipped with an axial feed system for machining the bottoms of grooves on flanges and valves in confined areas.