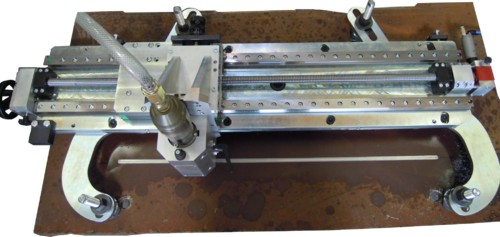

The SERCO milling unit is designed for carrying out numerous milling operations (surfacing, slot-milling, beveling, drilling, tapping, cutting with a milling saw, etc. On flanges or sheeting, on site or in the workshop. It can be used flat or on a vertical axis as required. Its clamping and adjustable foot system provides it with a machining capacity of up to 1025,4 mm (40.35”). Its ease of use, rigidity, flexibility of adjustment and high machining capacity make it a highly versatile tool.

Technical Features

Data sheet

Dimensions

We also propose

TU1100 Flange & Valve Facing Equipment. Portable lathes for sealing surfaces, flanges and bores

0 mm (0.00") ID

1100 mm (43.31") OD