E-newsletters Company news

Machininga by-pass connection weldedon a valve located in a nuclear facility.

Description of Needs:

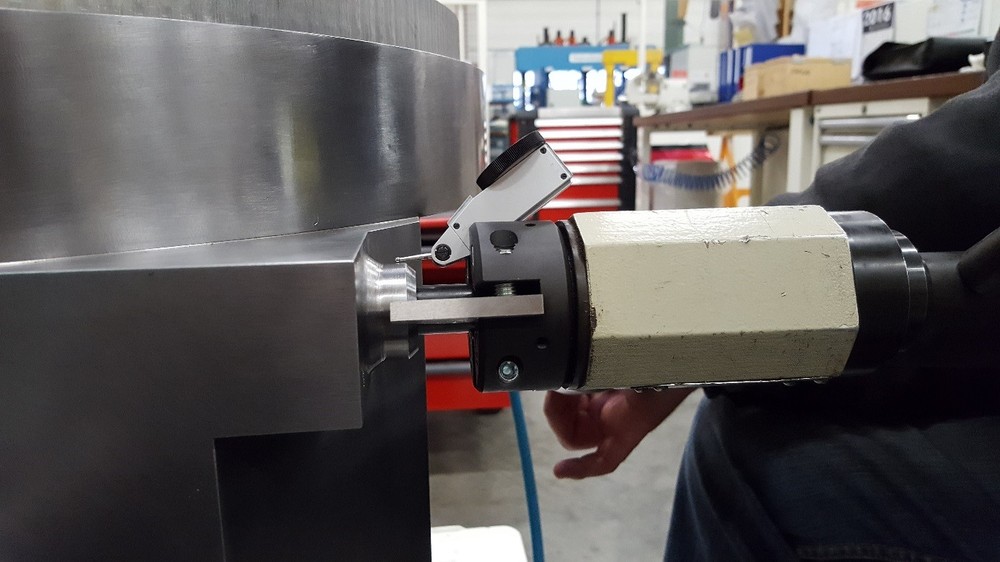

Machining a by-pass connection welded on a valve located in a nuclear facility.

The angle and the root face of the connection failed to meet the specifications for the welding operation.

The installation of the valve on a lathe is very complicated.

SERCO has, therefore, been requested to machine this connection directly on-site while respecting the dimensions and the tolerances of the drawing (0.1 mm (.004”).

ID of the connection: 25 mm (1”).

OD of the connection: 34 mm (1.339”).

Tolerance of the root face dimension: 0.1 mm (.004”).

Equipment Used:

PROTEM US25 pipe beveling machine with pneumatic drive.

Mandrel - Ø 18 mm (.709”).

Specific tool bits.

Protective collet for the ID of the connection.

Response Time:

Assembly of the machine.

+ adjustment of the machine in the connection.

+ machining of the connection.

+ disassembly of the machine.

TOTAL : 20 minutes

Result:

The customer performed a control with the use of a wax molding.

The result was verified to the tolerances requested.

The use of a portable machine avoided the need to install the valve on a conventional lathe.

The adjustment on a lathe would have required a great deal of time. In addition, the accuracy would not have been guaranteed.

Only the PROTEM machine was rigid and accurate enough to perform such a machining.