E-newsletters Company news

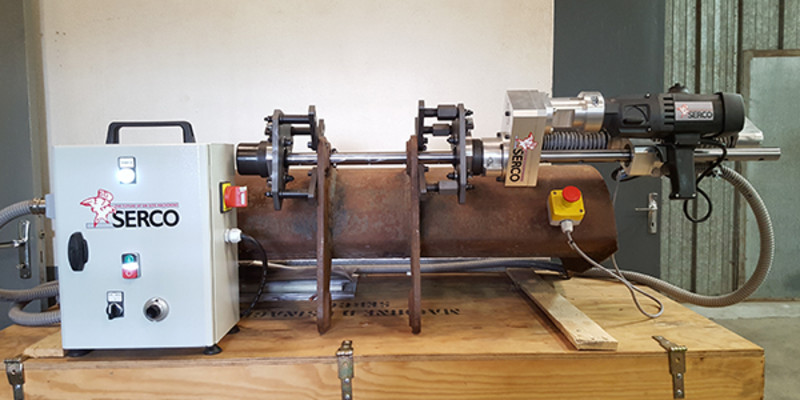

The machine can be set up easily and rapidly. The SERCO SBM1 boring bar can be precisely adjusted in concentricity and parallelism to an accuracy of 0.01mm. Compact and light-weight, the SERCO boring bar is the perfect tool for all your on-site machining operations. Its technology enables facing operations to be carried out over a few millimeters and boring up to 285mm depth (11.2”). Robust, reliable, ergonomic design, small dimensions.

TECHNICAL FEATURES:

- Axial movement: 285mm (11.2”)

- Axial auto-feed: 5 to 30 mm/min

- Machining Ø: 38 to 150mm

- Rotation speed: 50 to 120 rpm

- Min & Max length of the machine: 100mm to 1950mm

- Maxi power electric driving motor (230 V): 1050 W

- Weight: 53 kg

Powerful electric drive with emergency stop mounted on a magnet in order to be positioned at the closest point to the machine. Axial feed drive in order to control tool feed speed and, in consequence, roughness of the machined surface. The two bearings that hold the bar are knuckle bearings and can be set up with three ball screws in order to perfectly align the bar with the boring. Regarding the drive, fixation is mounted on columns to align the drive with the bar.

This machine is electrically driven and complies with all applicable norms. A control unit controls the entire machine to safely perform operations. The remote control monitors tool rotation and axial feed speed as well. A digital ruler is clamped on the axial feed in order to know precisely the measurement of each tool movement. The wheel and the worm screw enabling the axial movement are protected from chips by a gusset, to avoid the locking risk for the machine during machining.