E-newsletters Company news

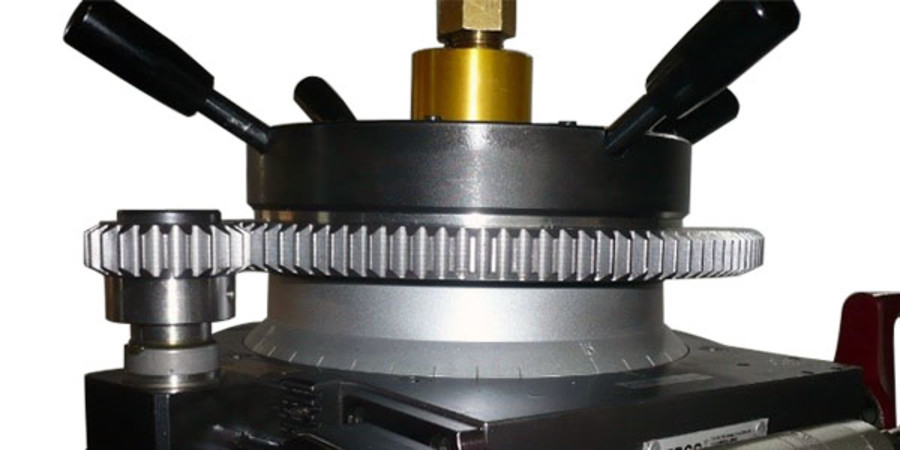

The TU machine set-up is fast and easy. A parallel orientation toward the machining surface is aligned by adjusting the height of the columns. A second step, completely independent of the first, adjusts the concentricity with positioning screws. A dial gauge controls both adjustments to an accuracy of 1/100 mm. The surface finish reaches up to Ra 1.6.

Conical machining operations can be performed with the optional AC38 or the RTJ device where the radial and axial velocities are interconnected.

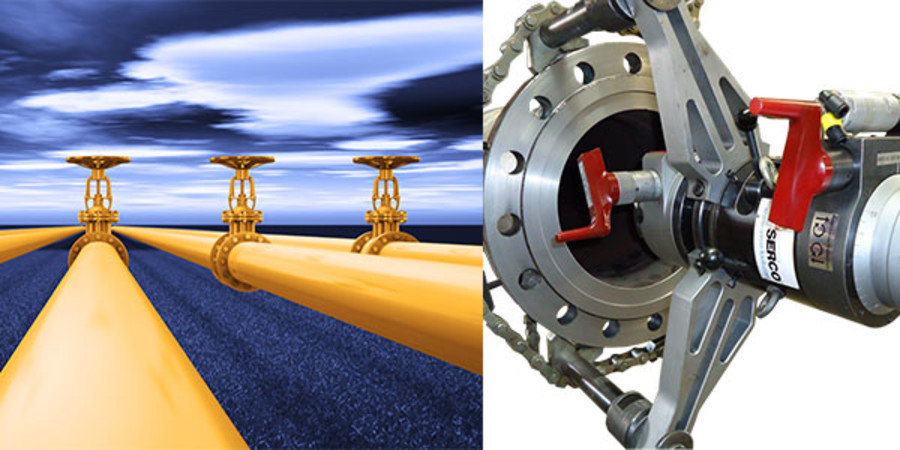

Designed on the basis of a standard TU 600, this machine is fully automatic and power-driven by brushless motors (rotation and axial and radial feed movements). The machine is remote-controlled by an axis interpolation technique in order to carry out highly complex and varied machining operations in addition to normal boring and facing functions