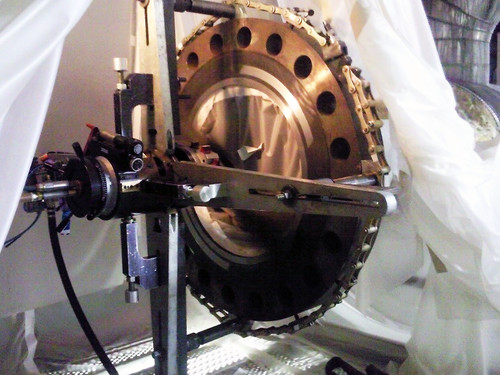

Check-valve machining in a nuclear power plant

Repairing sealing surfaces and dowel pin guides on a check-valve flange and the piping flange, following a distortion problem due to over-tightening.

Description: Repairing sealing surfaces and dowel pin guides on a check-valve flange and the piping flange, following a distortion problem due to over-tightening. Machining outage units O.D. 1150 mm (45.275”).

Tolerances to be maintained: 0.05 mm (.020”)

Machine: SERCO TU 1200 attached to a FC 1150

Result: Machining completed in compliance with tolerances.