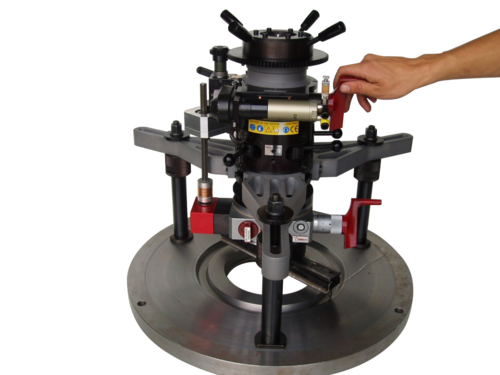

0 mm (0.00") ID

1100 mm (43.31") OD

Making RTJ groove bearing surfaces:• Conical machining – Machining 2 slopes, inside and outside at anangle of 23° to vertical.• Groove machining Conical machining for RTJ groove bearing surfaces is done using an automatic feed combining the radial and axial feeds on the SERCO portable machine.Angular accuracy / Machining accuracy: 0.01 mm / Surface finish: Ra 1.6.