Flanges

A flange is a disk, collar or ring connected to a pipe to form a link with other piping elements (valves, other pipes, etc.) or to block off a part of the piping. Flanges are normally welded or screwed onto pipe ends and connected together by bolts. A gasket or seal is inserted between the two flanges to make sure that it is liquid or gas tight. Several official organizations have published specifications (ANSI, ISO, etc.) which supply information on dimensions and pressures to be taken into account depending on temperatures.

Different Types of Flanges

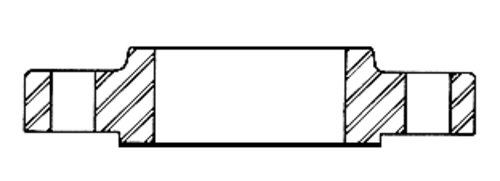

Slip-on Flanges

This type of flange is machined with an ID slightly larger than the pipe OD. This enables the flange to slide along the pipe, but it remains close to the pipe surface at the same time. Flanges are then held in position by welding them at the top and bottom.

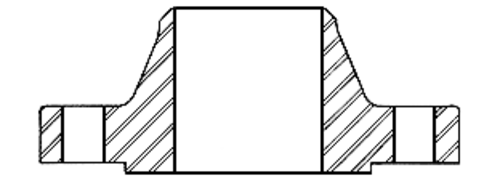

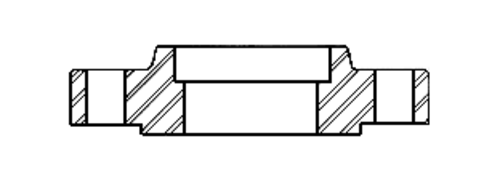

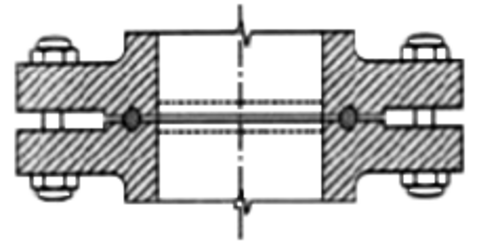

Welding Neck Flanges

These flanges are held by welding the pipe onto the neck of the flange. This enables any stress on the flange to be transferred towards the pipe and to reduce stress concentrations on the base of the flange. Welding neck flanges are often used for high pressure applications. The flange I.D. is machined to match the pipe I.D.

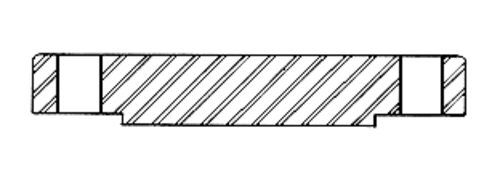

Blind or Blank Flanges

Blind or blank flanges are used for sealing the end of a piping system or a pressure tank. They are also used for testing gas or liquid pressure in a pipe or a tank. This type of flange also provides easy access inside piping whenever required. They are used for high pressure applications.

Overlapping Flanges

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

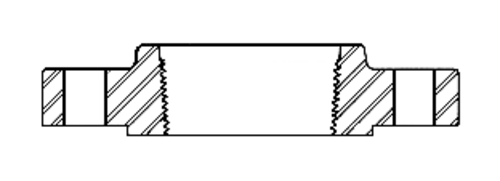

Threaded Flanges

Threaded flanges can only be used with threaded pipes. Their advantage is that they can be connected without welding. These flanges are often used with small diameter pipes at high pressure.

Socket Weld Flanges

Socket weld flanges are normally used with small diameter pipes and in high pressure environments. Flanges are held by inserting the pipe into the flange and welding the top of the flange on the outside. This enables the inside of the pipe to be kept smooth so that the fluid or gas can circulate more easily.

Different types of Flange Sealing Surfaces

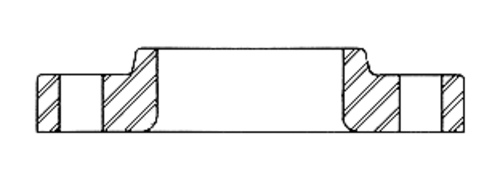

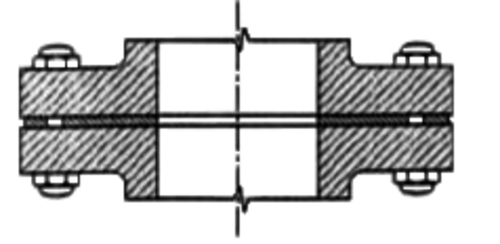

Raised Faces

Raised face flanges are the type of flanges most commonly used in treatment plants and are easy to identify. Their name comes from the fact that the contact surface is raised in comparison with the face where the bolt holes are located. This type of flange enables a wide range of different seals to be used. High pressure can be exercised on a small contact surface and in this way, the fluid-containing capacity of the seal is increased.

Flat Sealing Surfaces

Flanges with flat sealing surfaces have a contact surface that is on the same level as the surface where the bolt holes are located. This type of flange is often used where flanges are cast.

Flanges with flat sealing surfaces are never used together with flanges that have raised faces.

RTJ Joints

RTJ joints are used for high pressures (Class 600 or over) and/or high temperatures (above 427°C (882°F) ). They feature machined grooves in which a metallic ring joint is fitted. When the bolts are tightened, the metal joint is compressed between the two flanges and is deformed so as to create a metal-to-metal contact. An RTJ type flange may have a raised face with a machined groove. But this face does not play any role in the sealing capacity of the unit.

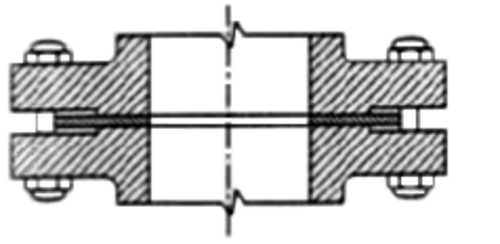

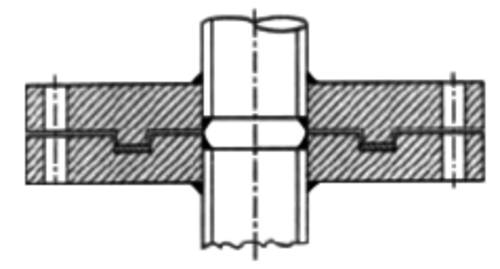

Tongue and Groove Flanges

Tongue and groove flanges have faces that need to be used in pairs. One of the flanges has a machined groove in its bearing surface, while the other has a tongue that is inserted into the groove. They are often found on pump covers and valve bonnets.

Their advantage lies in the fact that the two flanges are automatically aligned and form a reservoir for bonding. Moreover, the wedge seal maintains the load axis in line with the seal.

RTJ and T&G flanges must never be mounted together. This, because their contact surfaces do not correspond and no seals exist whose shape corresponds to one type of flange on one side and another type of flange on the other.