85 mm (3.35") ID

300 mm (11.81") OD

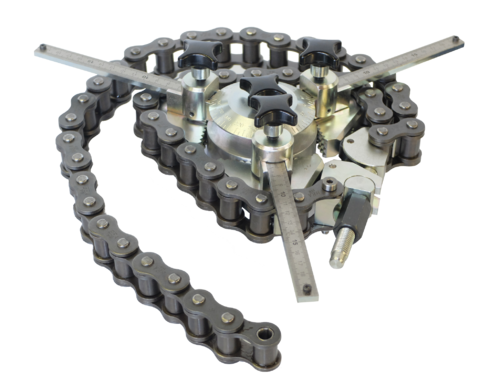

SERCO machining units can be attached to the outer surfaces of parts (flanges, valves, etc) with the FC300. This means that dowel pinbearing surfaces (or other surfaces) can be completely machined. Thanks to its simple functional design, the unit can be set up in any position in a few minutes by a single operator. For use with TU200 and TU400 machines